First manufacturing process in the industry

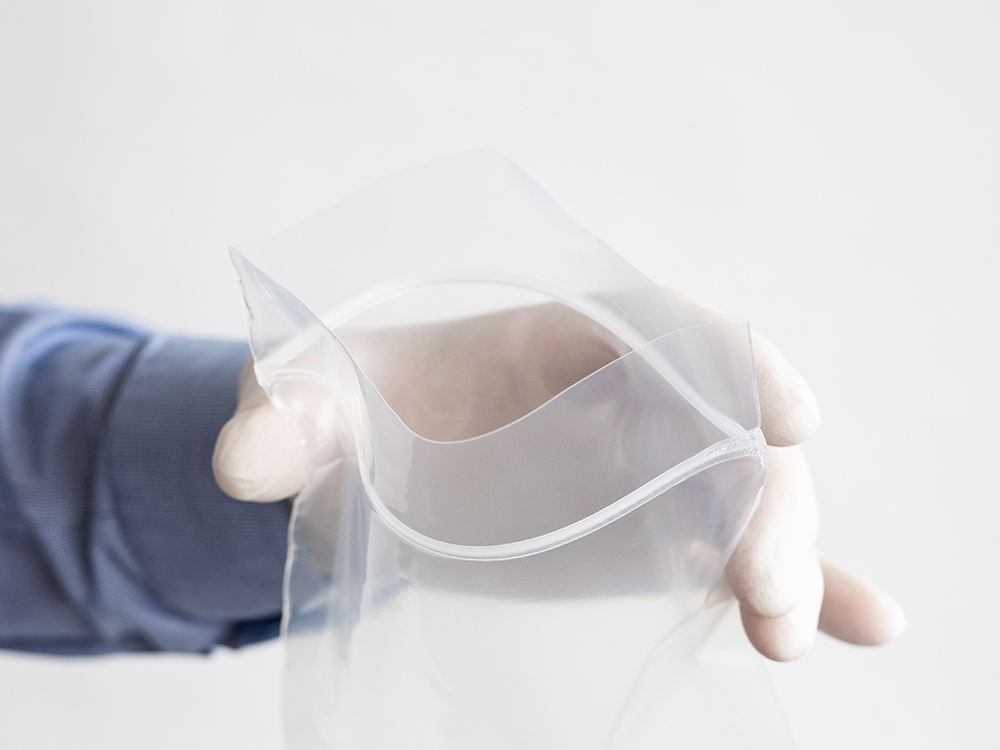

Pre-opened zipper-bags

Zipper-bags are only produced in a sealed state. This used to be the standard practice. That is exactly what we wanted to change, so we have developed the industry’s first manufacturing process for producing pressure seal bags that are already in an open state.

Opened zipper-bags

Development Process

Background

Pressure seal bags are one of the most reliable packaging solutions – whether for commissioning, storage or shipping. They ensure that loosely packed products do not slip out of the outer packaging and get damaged or contaminated. The bags are designed to be opened and closed by an integrated seal that responds to applied pressure. They are usually produced in a sealed state. The pouches then reach the customer and user through a retailer or directly.

Challenge

Before the bags can be used, the pressure closure – which is also known as a “zipper” – must be opened along the seam. In many areas of application, this means that the opening process causes additional time and labour costs – for example, when used in time-controlled packaging lines or in technical / medical procedures. In the case of the latter in particular, strict hygiene regulations apply and disposable gloves must be worn, for example. Having to open the pressure seal first therefore takes more time and effort.

Idea

We are developing a manufacturing process that enables zipper-bags to be produced in an already opened state. This has two advantages for users: The time-consuming pre-opening of the bags is no longer needed and the packaging represents a cost-saving alternative to the usual sealed version.

Result

We have developed ideas and come up with new designs as we have experimented and made constant improvements. The result is a completely new production process in which we have remained true to our standards of quality and customisation. After more than three months of development, we have been able to supply our customers with pressure seal bags in an open condition since May 2021. As with all of our products, production takes place in-house at our headquarters in Wiehl-Drabenderhöhe.

Remaining open for new ideas!

“Zipper-bags are only produced in a closed state on the European market using standard procedures. We wanted to change that and offer pre-opened pressure seal bags that are “Made in Germany”.

Our team has put a lot of work into the development process and it has paid off: with the new manufacturing method, we can offer our customers real added value – financially and in terms of the process.”

Axel Hackbarth, Managing Director

Remaining open for new ideas!

“Zipper-bags are only produced in a closed state on the European market using standard procedures. We wanted to change that and offer pre-opened pressure seal bags that are “Made in Germany”.

Our team has put a lot of work into the development process and it has paid off: with the new manufacturing method, we can offer our customers real added value – financially and in terms of the process.”

Axel Hackbarth, Managing Director